Sustainability

Responsible Sourcing

We source responsibly

Electromobility is one of the key solutions to merge the global desire for individual and sustainable/green mobility.

As a global leading supplier of battery materials for lithium-ion batteries, we aim to contribute to source battery materials responsibly to have a positive impact on the people working in our supply chain.

Responsible sourcing of minerals

The production of Precursor Cathode Active Materials (PCAM) and Cathode Active Materials (CAM) involves various mineral raw materials such as cobalt, lithium, nickel, aluminum, and manganese.

Raw materials are sourced responsibly as a guiding principle of us. When sourcing minerals, companies may face challenges in the areas of environment, health and safety, and human rights.

We are committed to foster a responsible and sustainable global supply chain of raw materials, including cobalt.

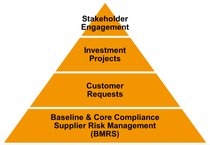

To effectively respond to risks related to sourcing of minerals, BASF has adopted a specific due diligence approach that complements our general corporate sustainability in procurement management system.

Besides, BASF actively engages outside the responsible sourcing compliance. BASF promotes responsible sourcing through industry and multi-stakeholder initiatives and NGO dialogs.

Additionally, BASF investment decisions respect ESG and responsible supply chain criteria. Furthermore, BASF aims to fulfil the ambitious customer requests for responsible supply chains.

Compliance through Supplier Risk Management

Based on the German Supply Chain Act (LkSG), the upcoming Corporate Sustainability Due Diligence Directive (CSDDD) EU Battery Regulation, as well as the OECD Due Diligence Guidance for Responsible Supply Chains, supply chain risks need to be assessed. BASF Battery Materials evaluates these risks based on our Battery Minerals Responsible Sourcing Management System (BMRS) as well as according to our Supplier Code of Conduct.

BASF aims for a third-party verification of our supply chains through independent industrial standards, e.g. Responsible Minerals Initiative (RMI), Initiative for Responsible Mining Assurance (IRMA).

BASF operates a globally applied corporate due diligence management process to identify and manage ESG risks in its supply chains. BASF's corporate due diligence management and compliance hotline are subject to annual third party audits.

Battery Minerals Responsible Sourcing Management System

The Battery Minerals Responsible Sourcing Management System applies to all Tier-1 suppliers across different BASF's entities that buy cobalt, lithium, manganese or nickel. It also applies to all Tier-n suppliers with substantiated knowledge.

Our engagement in industry and multi-stakeholder initiatives

Understanding the challenges and risks for the industry, we aim to achieve more meaningful impacts in terms of the UN Sustainable Development Goals.

The active engagement of BASF in industry and multi-stakeholder initiatives helps to increase the influence over suppliers and mitigate the risks in the supply chains.

BASF actively engages in various initiatives

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ)

Lithium Initiative & Cobalt for Development.

Responsible Minerals Initiative (RMI)

RMI aims to increase the transparency and industry standards of refiners and smelters through a third-party audit to assign a certificate to the refiners and smelters. RMI offers companies and their suppliers an independent, third-party audit that determines, which smelters and refiners can be verified as having assurance systems in place to manage risks related to gross human rights violations, corruption and conflict.

Cobalt Institute

The Cobalt Institute is a global association that represents the cobalt industry, promoting sustainable and responsible production, and serves as a platform for collaboration among producers, users, and traders.

Initiative for Responsible Mining Assurance (IRMA)

IRMA aims to increase the transparency and industry standards of mines through a self-assessment and third-party audit to assign a certificate to the mines.

Global Battery Alliance (GBA)

The GBA aims to promote dialogue between the various stakeholders and to develop standards and tools to make the battery value chain socially responsible, environmentally and economically sustainable, and innovative.

Responsible Critical Mineral Initiative (RCI)

The RCI aims to identify, prevent and address the social and environmental challenges of critical minerals supply chains.

Learn more